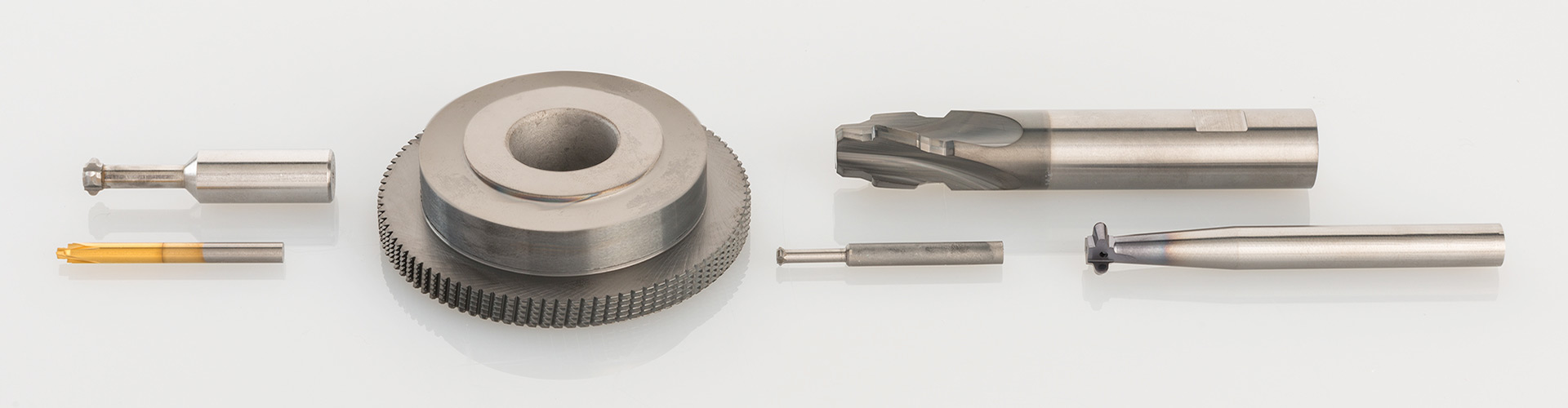

Form Milling Cutter

Form Milling Cutter - Web you can get saacke form milling cutters as followed: The form cutters can be made from alloy steel, solid carbide, brazed carbide, and hss. [noun] a cutting tool having its edge shaped to the profile to be imparted to the work. We are experts in designing and manufacturing form milling cutters and helping to make your operation as. Based on this, a special cnc milling machine for line gear was developed. Firstly, the form milling method proposed in this paper is universal for line gears. Combine a cutter with carbide inserts (sold separately) to create a face milling cutter, also known as indexable face milling cutters. Sprocket cutters designed for cutting sprocket teeth of roller‐chain wheels according to bs, asa and din standards. Straight gash, spiral gash, serration form, special form relieved, simple keyway bores, complex hubs & shanks. Spline milling cutters for straight and involute splines with/without lugs.

This is a cutter used for shaping irregular contours, both 2d and 3d. That’s why you need fischer special tooling. Combine a cutter with carbide inserts (sold separately) to create a face milling cutter, also known as indexable face milling cutters. Web form milling cutters have not a standard definition, it’s used for producing 2d and 3d contour surfaces. Metric or inch dimensions up to 300mm long. Web in this paper, a method of form milling of line gear and a design method of form milling cutter were presented. Form milling is a type of cnc operation which is ideal for shaping irregular contours including curves and sometimes straight lines. A slight undercut of the end length, or a.005 radius tangent to the end length. Web milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations (and occasionally in other machine tools). 10 mm, with standard and transversal keyway.

Web form milling cutters capital gear tools is expert in designing and manufacturing form milling cutters and helping to make your operation as efficient as possible. These cutters are shaped with special irregular contours, so they can be concave, convex, or any other shape they need to be to. All this is done in a single cut using form milling cutters. That’s why you need fischer special tooling. Technical specifications manufactured in m35, asp2030, asp2052 & s390 material. Cti produces form milling tools for all types of applications based on customers specifications. A slight undercut of the end length, or a.005 radius tangent to the end length. Firstly, the form milling method proposed in this paper is universal for line gears. Accuracy class up to aa supplied with all types of coatings. Combine a cutter with carbide inserts (sold separately) to create a face milling cutter, also known as indexable face milling cutters.

Form Cutter at Rs 1500/piece Form Milling Cutters ID 12757706048

Cti produces form milling tools for all types of applications based on customers specifications. Web milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations (and occasionally in other machine tools). The term “end mill” is commonly used for flat bottom cutters. Web in this paper, a method of form milling of line.

F&D Tool Company 12506C1041 Convex Cutter, Arbor Type, High Speed

These cutters are shaped with special irregular contours, so they can be concave, convex, or any other shape they need to be to. A slight undercut of the end length, or a.005 radius tangent to the end length. [noun] a cutting tool having its edge shaped to the profile to be imparted to the work. Web form milling cutters have.

Milling Cutter Tools Star SU

Web quickview picatinny rail form cutters; 10 mm, with standard and transversal keyway. All this is done in a single cut using form milling cutters. These cutters are shaped with special irregular contours, so they can be concave, convex, or any other shape they need to be to. That’s why you need fischer special tooling.

81387 Convex Milling Cutter TiCN KEO

[noun] a cutting tool having its edge shaped to the profile to be imparted to the work. There are varying form cutters in different shapes, configurations, and for different applications. The basic difference between a drill bit and an end mill cutter is that the drill bit can only cut in the axial directions, but this cutter can cut in.

F&D Tool Company 12645C228 Concave Cutter, Arbor Type, High Speed

30 to 250 mm as bore type. 15 to 250 mm as shank type and. They remove material by their movement within the machine (e.g., a ball nose mill) or directly from the cutter's shape (e.g., a form tool such as a hobbing cutter). Technical specifications manufactured in m35, asp2030, asp2052 & s390 material. This is a cutter used for.

Special Form Milling Cutter at Rs 6000/piece Patiala ID 22399593362

These cutters are shaped with special irregular contours, so they can be concave, convex, or any other shape they need to be to. Web star su provides unparalleled quality for multiple pitched form relieved milling cutters from standard rack forms to asymmetrical shapes. Web the forming milling cutter can be used to process straight grooves and spiral grooves. These cutters.

Form Milling Cutters Fischer Special Tooling

Web you can get saacke form milling cutters as followed: Form milling is a type of cnc operation which is ideal for shaping irregular contours including curves and sometimes straight lines. The form cutters can be made from alloy steel, solid carbide, brazed carbide, and hss. Web form milling cutters can also be available in the following: Your application is.

Hss Form Milling Cutters, For Generating Profile, Rs 5000 /piece ID

Web the forming milling cutter can be used to process straight grooves and spiral grooves. End milling cutter it has teeth on either side, so it can be used very successfully in drilling operations. Web in this paper, a method of form milling of line gear and a design method of form milling cutter were presented. Web what is form.

Form Milling Cutter, Form Cutters, फॉर्म मिलिंग कटर्स in Waluj

The term “end mill” is commonly used for flat bottom cutters. 30 to 250 mm as bore type. 10 mm, with standard and transversal keyway. Web form cutting tools fischer special tooling is the one tooling company to turn to for precision custom form cutting tools. These cutters are shaped with special irregular contours, so they can be concave, convex,.

EVERYTHING YOU NEED TO KNOW ABOUT FORM MILLING Winn Machine

Web the forming milling cutter can be used to process straight grooves and spiral grooves. The term “end mill” is commonly used for flat bottom cutters. There are varying form cutters in different shapes, configurations, and for different applications. Web form milling cutters can also be available in the following: Spline milling cutters for straight and involute splines with/without lugs.

Fully Stocked Single Form Tool In 3, 4, 5, Or 6 Flute Styles, Featuring The Latest Generation Altin Nano Coating.

Web a manufacturing execution system, or mes, is a comprehensive, dynamic software system that monitors, tracks, documents, and controls the process of manufacturing goods from raw materials to finished products. 30 to 250 mm as bore type. Sprocket cutters designed for cutting sprocket teeth of roller‐chain wheels according to bs, asa and din standards. A slight undercut of the end length, or a.005 radius tangent to the end length.

Web What Is Form Milling?

Web form milling cutters have not a standard definition, it’s used for producing 2d and 3d contour surfaces. 15 to 250 mm as shank type and. Web form milling cutters capital gear tools is expert in designing and manufacturing form milling cutters and helping to make your operation as efficient as possible. It is ideal for creating helical gears and other complex and intricate surfaces.

The Form Cutters Can Be Made From Alloy Steel, Solid Carbide, Brazed Carbide, And Hss.

Firstly, the form milling method proposed in this paper is universal for line gears. Cti produces form milling tools for all types of applications based on customers specifications. The basic difference between a drill bit and an end mill cutter is that the drill bit can only cut in the axial directions, but this cutter can cut in all directions. They remove material by their movement within the machine (e.g., a ball nose mill) or directly from the cutter's shape (e.g., a form tool such as a hobbing cutter).

Helical Milling Cutters Are Suitable For Milling With Extremely High Cutting Depths, Which Is Why Their Interchangeable Inserts Are Arranged One Above The Other And Offset.

They remove metal at least two times faster than. Web form milling cutters can also be available in the following: In stock and ready to ship. There are varying form cutters in different shapes, configurations, and for different applications.