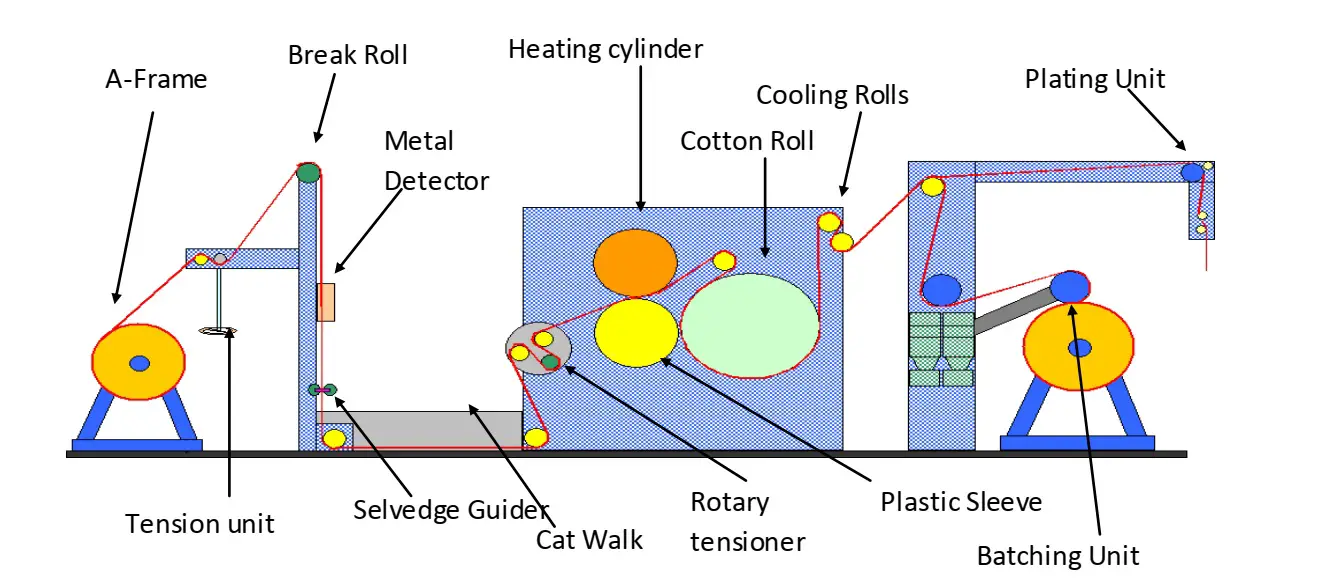

Calendering Of Fabric

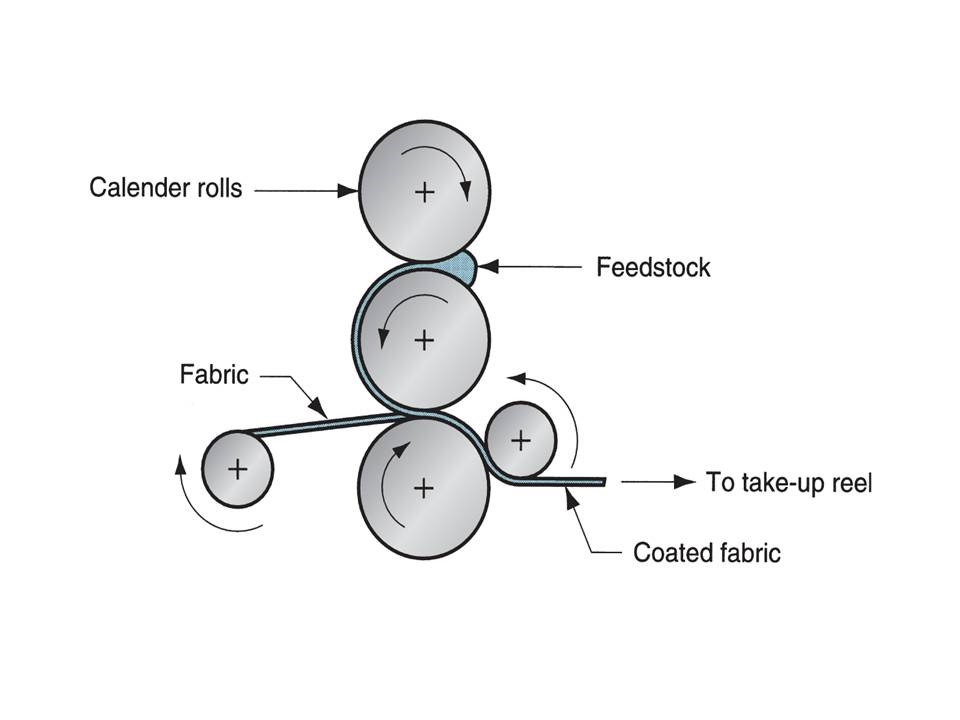

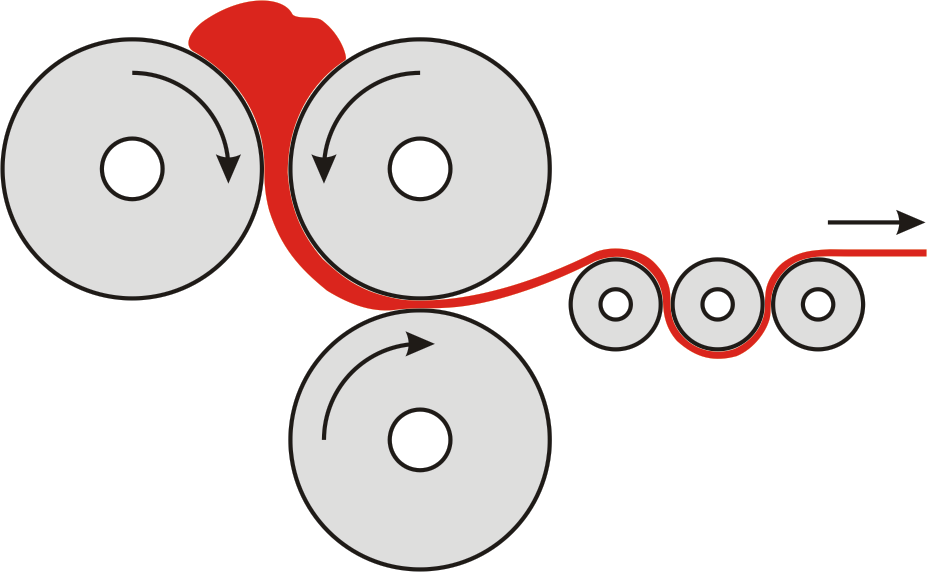

Calendering Of Fabric - Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as.

Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under.

Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability.

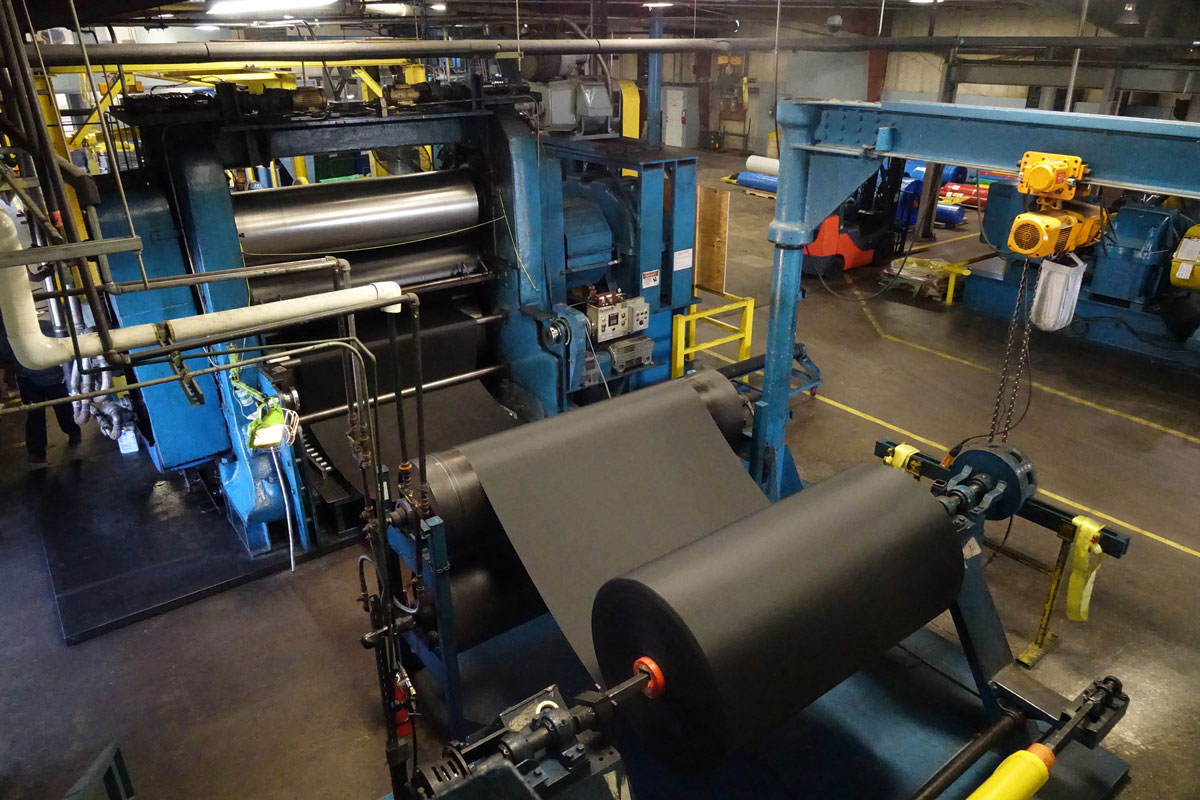

Machinio Newest Categories Calendering & Carding

Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as. Web calendering is a process whereby fabric is compressed by passing it between two or more.

fabric Calendering process, caledar laundry, electric press machine for

Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability. Web.

10 Facts About Calendering in Textile! Textile Property

Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability. Web a calender is a series of hard pressure.

CSI Calendering, Inc Textiles

Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties.

Calendering for Filter Cloth Finishing Micronics Inc

Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as. Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web.

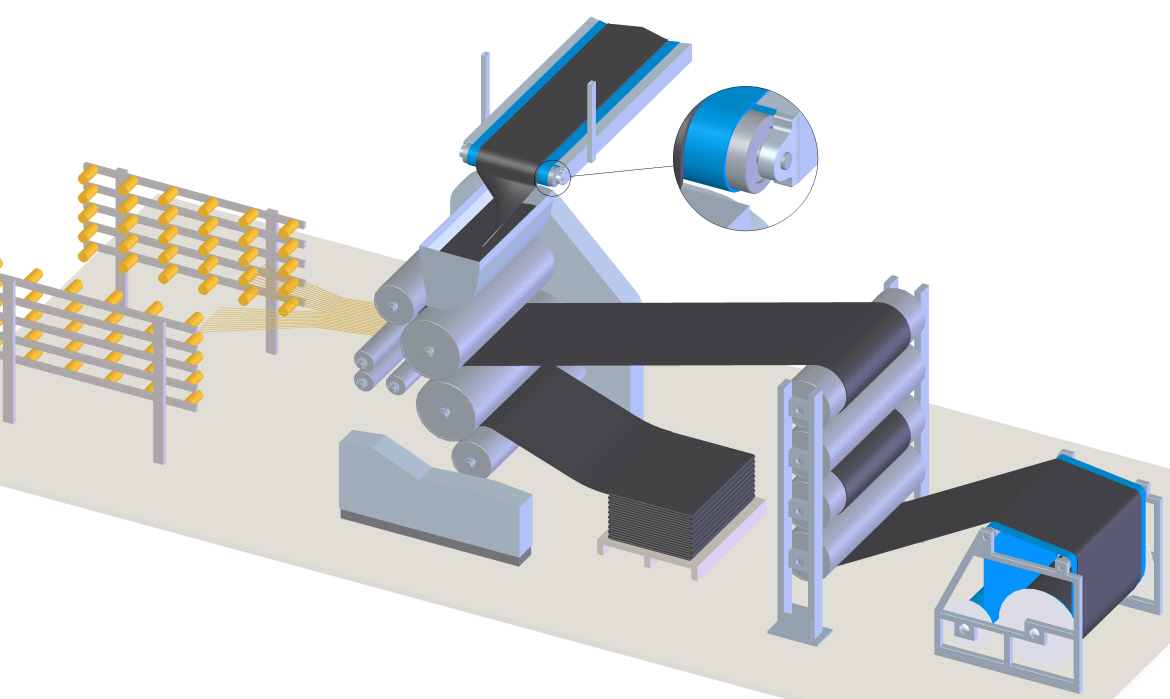

Tyre Manufacturing Ammeraal Beltech

Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability. Web.

6 Types Of Calendering Process In Textile Textile Property

Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability. Web.

Calendering Factors Effecting Calendering Calendering Machine

Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as. Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web a calender is a series of hard pressure.

6 Types Of Calendering Process In Textile Textile Property

Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web.

Calendering:Woven Fabric Finishing Process textilewebinfo

Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as. Web.

Web Calendering Is A Process Whereby Fabric Is Compressed By Passing It Between Two Or More Rollers Under.

Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as. Web a calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Web calendering increases fabric density and compacts fibers, resulting in improved fabric strength and durability.